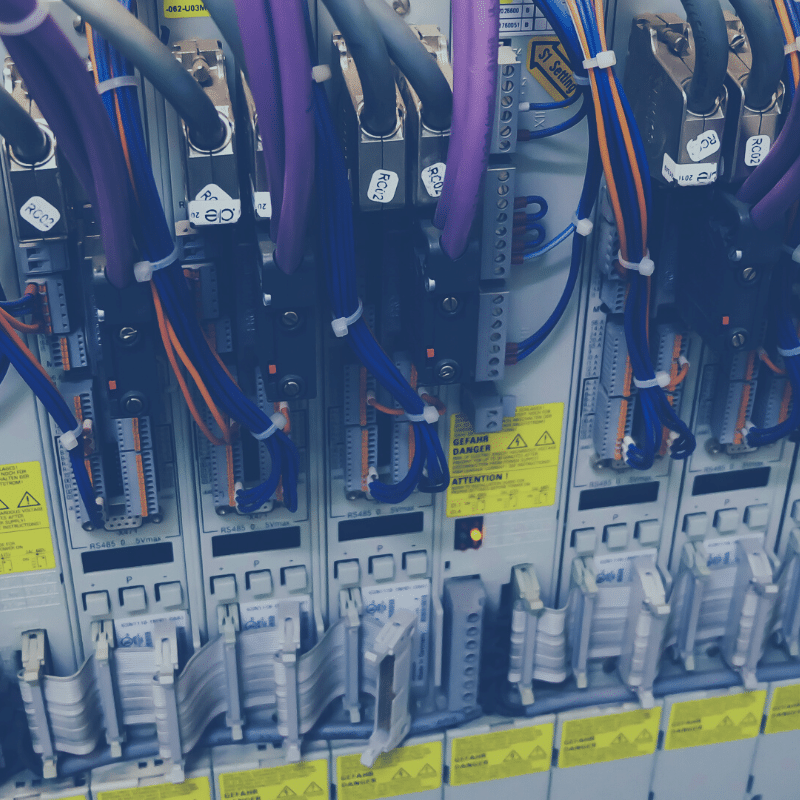

Programmable Logical Controllers (PLCs) are still the standard for manufacturing control in many modern industries. They are deployed to control processes, measure data, and perform tasks in harsh and complicated industrial environments.

PLCs have been the intelligence core for automation systems for decades, and while they have evolved to keep up with the advancement of industrial control processes, they still require manual configuration and maintenance. Here is where Industrial IoT (IIoT) technology enters as an industry disruptor.

Integrating PLC systems into the IIoT will undoubtedly add value and generate positive return for your business. But you may have learned that adding connectivity to PLCs is no easy task, as PLCs are generally hard-wired and lack interoperability. Or, you might have run into limitations with one of the preconfigured gateways that IoT-enables your PLCs.

So, how can you easily and affordably wirelessly enable your PLC? How can you create a system that is completely customized from the data collection system to the data visualization and data storage? This post will walk you through the three basic steps required to add cellular connectivity to your PLC.

Upgrading Your PLC for Wireless Connectivity

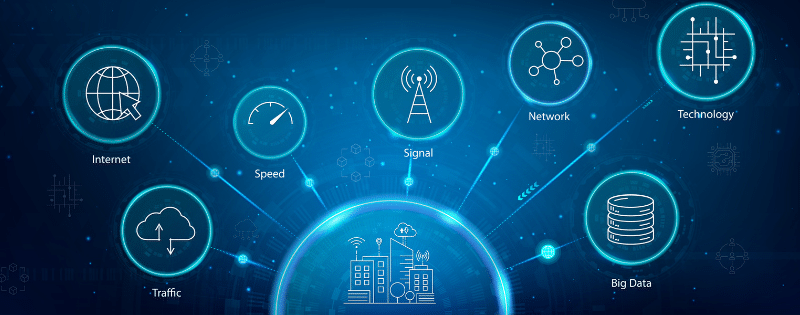

Think of PLC connectivity as having two ends: one end is the PLC, and the other end is the control system typically represented as a cloud application or database. In some workloads, like a function to report on PLC state condition, the PLC is a data producer, and the cloud system is the data consumer.

- PLC to Cloud: Query the PLC for tags, then send the tag information to the cloud. Tag can be any data the PLC has.

In others, like a function to reconfigure a PLC remotely, the cloud system is the data producer, and the PLC is the data consumer.

- Cloud to PLC: Alter the PLC, change a set point, change settings and variables, make remote control

Why Choose Cellular to Wirelessly Enable PLCs?

Wi-Fi still remains a challenge in complex physical environments like manufacturing facilities and warehouses. If you need to report on conditions, configure PLCs, or remotely control PLCs, you can’t afford network downtime. For wirelessly enabling your PLCs, cellular should be evaluated for suitability. Here are the key benefits of cellular connectivity:

- Reduced security risks: Cybersecurity is a critical consideration for anyone, but especially if you’re a vendor who supplies machinery with PLCs. Network security and IT professionals don’t want to add machines to their network, as this becomes an additional point of network vulnerability. Cellular allows you to bring your own network to the system, giving you control and oversight over secure connectivity.

- Always-on connectivity: Reduce the risk of downtime. Outages are rare with cellular networks because they are ubiquitous and offer redundant capability.

- No maintenance: Cellular networks are managed by the major carriers. Cellular connectivity does not require ongoing maintenance or network management like Wi-Fi.

3 Steps to Add Wireless Cellular Connectivity to Your PLC with Blues Wireless:

1. Assemble Your Connectivity Hardware

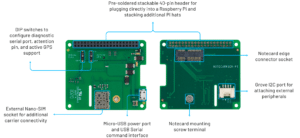

Plug the Notecard and Notecarrier into the Raspberry Pi.

What is the easiest and hardware to use that adds cellular connectivity?

The Notecarrier Pi/Raspberry Pi Hat is a drop-in host board for a Raspberry Pi or Pi-compatible Single Board Computer. It also provides antennae for both the GPS and cellular capabilities of the Notecard.

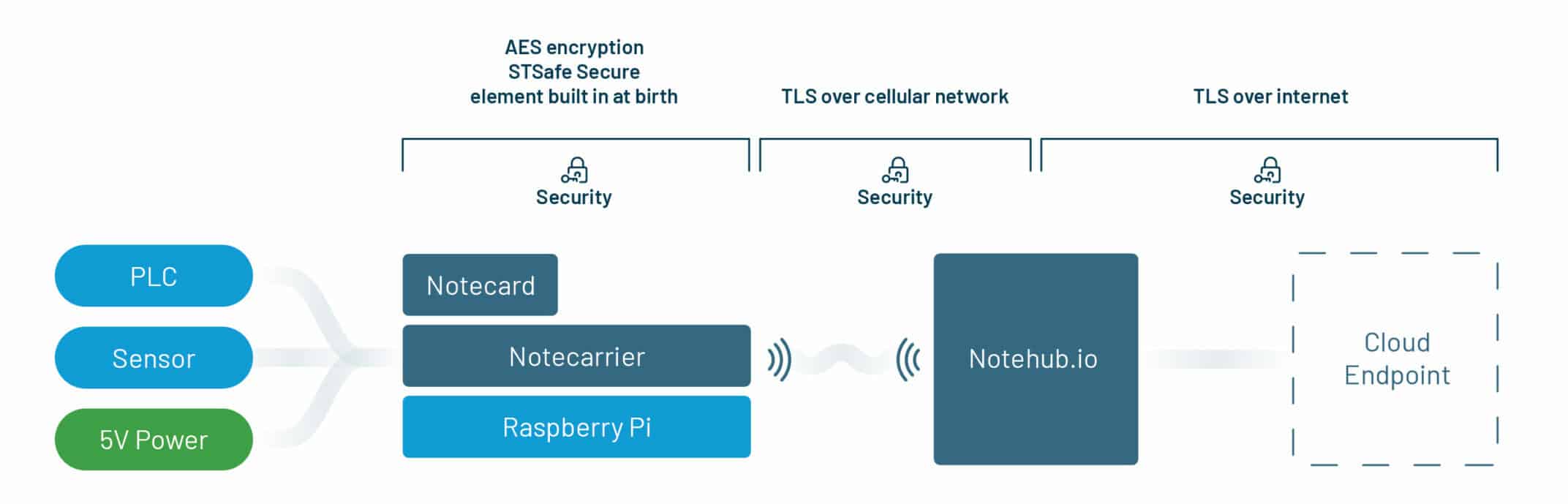

The Notecard plugs directly into the Notecarrier to create a cellular connection from PLC to cloud. It provisions itself to a global cellular network without any need for on-site configuration.

The Notecard also enables local processing for features like scheduling PLC data queries, remote data query configurations, arbitrary Modbus queries, and filtering data. You can leverage data filters to save on cellular transmission usage, only sending messages to the cloud when measurement values change rather than sending each measured value.

2. Enable Your PLC

Connect your PLC with the Raspberry Pi microcontroller with a crossover ethernet cable, (or you can use RS485 if you have that option available on the Raspberry Pi).

The Raspberry Pi will act as a Modbus client, sending queries over the ethernet cable to the PLC. In order for this to work you will need to know the IP address of the PLC, as well as how to query tags via Modbus for the specific PLC. This varies by PLC, and how tags are encoded.

You will need to know the data configuration of the specific tags on the PLC — that is, the address of the specific tags, and the size of the data stored by the tag ( 8 bits, 16 bits, 32 bits, etc.) This information is used to configure how the Raspberry Pi will query the PLC for the data you are looking for.

How will the PLC communicate with the wireless module?

The Raspberry Pi acts as a translator between cloud data formats (JavaScript Object Notation or JSON) and PLC data formats (Bit, Byte, Integer, Real, String).

3. Wirelessly Ship PLC Data

How will the data be routed to your endpoint (cloud application or database)?

Start routing PLC data through Notehub to your preferred cloud app or database.

PLC data will be read by the Raspberry Pi, and then handed to the Notecard to push the data to the cloud. The Notecard is cellular-enabled and communicates with the Blues Wireless Notehub via JSON API, which is human and machine readable.

The simple JSON format of the data is ready for integration with cloud applications, and includes timestamp information for the measured values, so you don’t need to maintain a real-time clock on your PLC system if you don’t have one already.

Where will the wireless module send data?

Notehub routes your data to any cloud application or database you desire, and enables you to manage devices and fleets, so you have full visibility and control of your IoT-connected PLCs.

How do I know my data will be secure during transport?

Data is sent and received by the Notecard securely, using off-the-internet communications over an encrypted channel and VPN tunnels.

For a more in-depth discussion on adding cellular connectivity to PLCs, check out our use case, “The Simple Way to Retrofit Your Programmable Logic Controllers (PLCs) with IoT”.

Conclusion

Just as PLCs have advanced in their capabilities as manufacturing and mechanical processes have evolved, so too has our need to update the way PLCs are controlled. Adding wireless communication and remote control functionality to your PLC will remove the need for manual processes and provide tangible benefits from the increased data visibility. Blues Wireless solves your connectivity challenges, provides robust data security, and allows you to customize sensors, hardware architecture, and data endpoints. And you can go from prototype to fleet deployment using the same hardware.

Ready to try it yourself? Get started with our Raspberry Pi Starter Kit.