Weed has now gone mainstream. Today, cannabis is big business.

Global sales are expected to reach nearly $149 billion by 2031, with a UN estimate putting the number of worldwide customers and patients at 188 million.

In the US, medical legalization in 37 states is changing public attitudes about recreational use, creating a booming new industry. But lack of legalization at the federal level and over-regulation at the state level are causing serious challenges throughout the supply chain.

The legacy cannabis industry is at a tipping point.

Internet of Things (IoT) technology is emerging as a way for cannabis cultivators to improve efficiency and profitability and comply with regulatory controls. By leveraging sensor data and analytics, businesses can reduce risk, increase profits, and improve customer service, making IoT solutions a powerful tool for success in this growing market. Much like the fresh floral industry, which is not unlike cannabis, technology will be an integral part of the shift toward a more efficient supply chain.

In this article, Blues speaks with Haerah Baird, a Cannabis Consultant specializing in supply chain optimization, covering the challenges currently being faced in California, and what could help ease the burden on the industry. We then look at specific IoT solutions in cannabis cultivation technology that have the potential to disrupt the industry and help growers scale. A quick acknowledgement that cannabis is a complicated topic, and this article barely scratches the surface – we’ll continue to cover important issues and emerging cannabis tech in the future.

Can you give us a quick overview of the cannabis industry?

There are so many things to say about the cannabis conundrum. In California, we see the intense regulations and high taxation at the state level make doing business expensive and nearly impossible for small operators. The flood of investor money and individuals seeking to participate in the “green rush” have actually contributed to the market volatility and instability.

These kinds of issues are felt throughout the supply chain, but I think cultivators feel them the most because they’re foundational to the supply chain.

How do cultivators track cannabis from seed to sale?

In California, we use a system called METRC, which tracks cannabis from seed or clone through harvest, processing, and distribution. It can provide full regulatory transparency throughout the supply chain and allow consumers to see product source information. At the cultivator level it’s particularly burdensome because for every operational activity on the farm, there is an associated action in METRC. Batches are retagged with RFID tracking basically any time the product changes form or licenses, all the way through distribution.

There’s not really a way to automate these built-in regulatory “brakes” and this affects scalability. It’s also incredibly wasteful and environmentally harmful as each tag is a piece of single-use plastic.

Seems there are lots of opportunities for technology use. What are the challenges?

A major challenge still affecting us right now is that the industry had to start from scratch. Businesses often piece together their own cannabis equipment and tech since cannabis remains illegal at the federal level.

We often use food-related machinery and equipment for packaging, but those who have a lot of hands-on experience working with cannabis understand it’s not usually that straightforward. Repurposing machinery to operate at scale can affect product integrity.

If you’re developing new tech, the complexity of working with cannabis products in an intensely regulated environment means you’ll get the best input from experienced cultivators and operators. However, those knowledge-holders are often left out of the conversation.

How do you see technology changing the industry?

There are so many opportunities for technology throughout the supply chain, and I hope we see more as the industry matures. As cultivators and licensed businesses scale, there is a tipping point where they need to implement new technology and automate processes. There have been some moves towards IoT, things like AI monitoring to keep eyes on the plants all the time. Precision growing is a hot topic as we see changes from small-scale farms to high-tech agribusiness. It might be a really profitable venture for someone to explore IoT integration with METRC.

About Haerah Baird: Haerah is based in the Emerald Triangle region of Northern California and has worked in the cannabis industry since 2016. She specializes in supply chain optimization for small- and large-scale businesses across the state.

Innovative IoT Solutions for Cultivating High-Quality Cannabis

Controlled Environment Agriculture

Controlled Environment Agriculture (CEA) is a technology-based approach to growing plants that allows for precise control over environmental factors such as temperature, humidity, light, and CO2 levels. Farming is done in a greenhouse or indoor growing facility and allows for efficient, year-round production of high-quality crops.

CEA is becoming increasingly popular in the cannabis industry because it allows growers to create ideal conditions for their plants, resulting in higher yields and consistent quality crops. Systems can be highly advanced, incorporating AI and machine learning (ML) technologies to monitor and control the growing environment. These systems can adjust lighting, temperature, and humidity levels automatically based on data collected by sensors in the grow room. This allows for precise control over the growing environment, which can result in a more consistent product, higher yields, and advanced techniques like crop steering.

Cannabis Crop Consistency with IoT Sensor Technology

Cannabis growers face a complex challenge in ensuring consistent crop quality, as environmental factors can result in varied phenotypes, even in plants with the same genetics. It’s terroir on steroids. This makes it attractive but also incredibly frustrating, with product consistency being a critical outcome for commercial growers.

However, the cannabis industry is quickly embracing the latest technological advances to overcome these hurdles.

IoT (Internet of Things) technology is offering remote monitoring and control of cannabis crops to ensure precision agriculture, optimize cultivar expressions, and deliver a uniform final product. This technology uses several components, including:

Environment monitoring

Environmental factors must be under constant observation to avoid plant damage, mold, pests, and other issues. Temperatures may vary in greenhouses and indoor grow facilities, making multiple observation points necessary.

- Canopy management – Environmental sensors monitor microclimates (temperature, relative humidity, etc.) and data from many individual monitors are integrated into one observation dashboard.

- 3D microclimate mapping – takes system measurements and uses AI to build a weather map of the microclimates within the grow.

- Pipe and Tank sensors for electrical conductivity (EC), pH & temperature – EC, pH, and water temperatures imbalances can cause nutrient toxicity. This also monitors for the proper temperature for roots and mineral levels.

- CO2 – CO2 is used in most growth recipes, as it is critical for photosynthesis. In high amounts, it can still be dangerous to plants and especially to growers.

Light intensity monitoring

The importance of light intensity in cannabis growth cannot be overstated. Photosynthetically active radiation (PAR) affects the entire plant, and daily light integral (DLI) is the sum of all PPFD plants receive in 24 hours. Lighting intensity also affects water and nutrient management, which are essential for optimal plant growth.

Light deprivation techniques are widely used to trigger cannabis plants to start the flowering process.

- Photosynthetically active radiation (PAR) – PAR is measured in photosynthetic photon flux density (PPFD), which affects the entire plant from flowers to roots.

- DLI sensors – Potentially the most important light measurement, DLI is the sum of all the PPFD plants receive in 24 hours.

- LUX monitoring – measures the intensity of the light around the plants relative to the heat source.

- Water and nutrient management

- Substrate sensors for water content (WC), EC, and temperature – substrate sensors ensure optimal conditions, and results can create triggers based on the preferred settings.

- Nutrient level monitoring

- Irrigation optimization

Pest control

Integrated pest management systems (IPMs) are also necessary to prevent damage from biological threats by monitoring environmental conditions such as air quality, filtration, humidity, and positive pressure.

- Integrated pest management systems (IPMs) – IPMs prevent damage from biological threats by monitoring air quality, filtration, humidity, positive pressure, and other environmental conditions. This could also include AI monitoring.

Yield monitoring

Yield monitoring through data tracking is vital for determining success factors for each strain, their impact on yield, terpene (aroma and effect), and cannabinoid (THC and CBD) levels.

- Strain or harvest batch recipes – these are the recommended grow room settings for each strain at every growth stage, specific to location and environment.

- Cultivation data tracking – historical data can be accessed to understand success factors for each strain, impact on yield, terpene, and cannabinoid levels.

Commercial facilities require a much more extensive and integrated system, connecting each critical component into a centralized control and command center.

Cannabis Crop Steering with IoT

Crop steering is a growing method that manipulates plants by intentionally changing the environment. This agricultural technique is not new but has only recently been optimized for cannabis by using different software and hardware solutions that help growers create the perfect conditions. Growers are seeking strains with higher cannabinoid percentages, greater pest resistance, biggest flowers, or other desirable traits that maximize profit.

To be effective, environmental changes need to be done at an exact time in a cultivar’s growth cycle. IoT in cannabis crop steering collects and analyzes data from sensors that monitor environmental conditions such as light, temperature, humidity, and water, and then adjusts those conditions in real-time to optimize for vegetative or generative needs. Using aggregate data, growers create crop steering strategies to achieve their immediate and long-term production goals.

The Future of IoT in Cannabis Cultivation

The cannabis industry is facing a pivotal moment as it navigates regulatory requirements and strives for efficiency and profitability, and new technology is rapidly emerging as a solution for automation and data-driven decision-making. IoT can help cannabis cultivators achieve greater efficiency, higher yields, and better quality products while also complying with regulations and maintaining accurate records of their processes. As the technology becomes more sophisticated and affordable, more cultivators are expected to adopt IoT solutions to improve their operations and stay ahead of the competition.

Overall, IoT technology has the potential to revolutionize the way cannabis is cultivated, tracked, and sold. Although the industry will undoubtedly face challenges in implementing and adopting these solutions, the benefits of increased efficiency, reduced costs, and improved quality and compliance will make it a worthwhile investment for many businesses in the cannabis industry. With the right tools and strategies, cannabis cultivators can embrace the opportunities of this exciting new market.

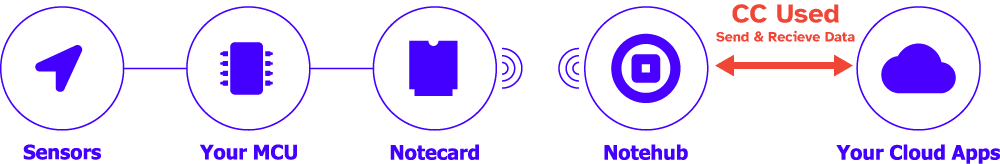

If you’re interested in learning more about building your own IoT solution for agriculture, see how AgroPatterns uses the Blues cellular IoT solution to remotely monitor greenhouses and maximize crop yield.