Summary

We’re currently experiencing disruptions in our transportation and logistics supply chain due to the COVID-19 pandemic that are highlighting existing inefficiencies. Cold chain delivery and is particularly impacted as populations around the world require direct delivery of food and medications, including the vaccine. Velvetwire’s StickerShockTM remote condition monitoring and tracking system provides real time data from manufacturer to local vaccination sites.

“The Blues Wireless team has been really responsive in understanding our needs and adapting the product to match what we need.” – Eric Bodnar, Founder & CEO Velvetwire

Tracking Assets in the Supply Chain

Today’s supply chain is complicated, with products changing hands up to 20 times in a typical global transit. There is no universal approach for tracking where something is, and prompt deliveries and accurate temperature conditions during storage and transport are critical for perishables in the food and pharmaceutical industries. Cold chain delivery is changing with the pandemic-affected economy’s increasing reliance on direct delivery of goods to consumers, and the extended shipping timelines we’re experiencing.

Shipping ports are closed or over-capacity, there is a shortage in ships and flights, and widespread labor shortages create conditions that prevent shipping from happening in a timely fashion. The traditional way of monitoring shipments has been to use a data logger. Data loggers are devices that attach to containers and log key data points during transport. The data is manually exported by a person who must locate the device and physically plug it into their laptop to transfer the information. This is not only costly and clumsy, but unless a shipment is intercepted, stakeholders receive insights after delivery.

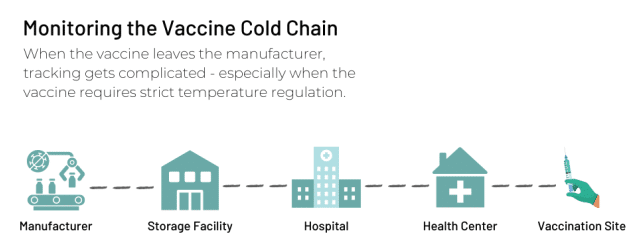

Vaccine Cold Chain Monitoring

COVID-19 vaccines have a shelf life of about nine months. Due to the protracted shipping schedules, deliveries that traditionally arrived in two to three weeks are now taking up to six months. These shipping delays can create unstable environments for vaccines as shipments sit at facilities and ports.

According to a UNICEF official, more than 100 million doses of COVID-19 vaccines distributed to poor nations have been rejected due to their expiration date. If shipment integrity can’t be verified, it is likely that the vaccines will be destroyed, and if pharmaceutical companies can’t get information on a timely basis, they can’t mitigate issues that are delaying shipment. This creates two critical issues:

- Revenue loss: Disruption of condition monitoring within a facility or transportation of component goods can lead to millions of dollars of losses per day.

- Insurance complications: It becomes difficult to assess who’s responsible for loss when dealing with insurance settlements. It is costly to determine that without any information.

Pharmaceutical companies have billions of vaccines totaling in the millions of dollars in a single container shipment, making condition monitoring a business-critical issue. With remote condition monitoring and tracking, shipping managers can accurately record the conditions and location of vaccines throughout the transportation process, thus ensuring compliance in the supply chain. All interested parties can be confident that the strict environmental conditions have been met so vaccines can be safely administered.

Remote Condition Monitoring with IoT

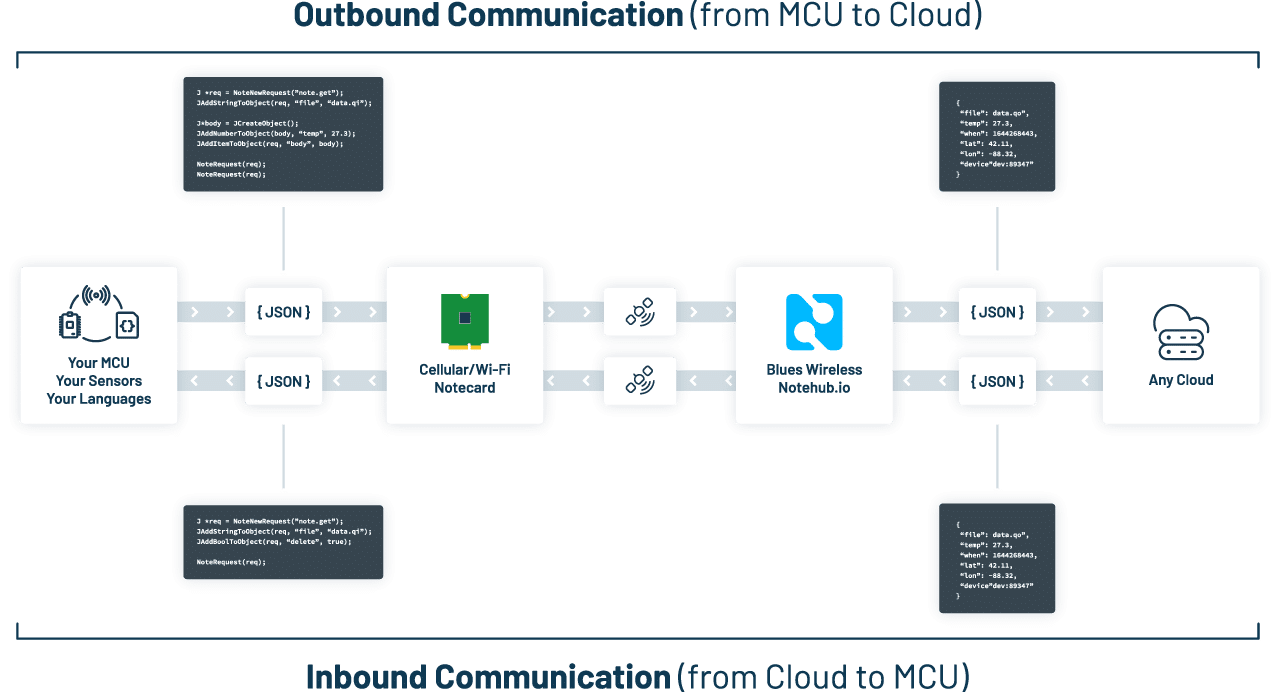

Velvetwire is partnering with global technology providers to modernize the cold supply chain and make remote condition monitoring ubiquitous. They provide smart-sensing connectivity and informatics in a low-friction product to ensure integrity of shipments to consumers. Their IoT device takes the utility of a data logger and supercharges it with internet-connected GPS and data tracking that includes real-time Condition, Location, and Identity (CLI) information.

Because data is stored in the cloud, it removes the need for human intervention, and how often data is recorded is configurable from once a day to once an hour. Beyond shipping perishable and fragile assets, remote condition monitoring can be used to track the location and condition of many things. This includes remote assets like wind turbines, critical machinery like wildfire response equipment, chemical tank storage, and more. The amount of information that can be tracked requires that the device be capable of hosting a suite of sensors:

- Temperature & humidity (pharmaceuticals)

- Breakage monitoring (microscopes)

- Vibration (chemicals)

- Impact and frost (remote assets)

Lightweight Connectivity with Blues Wireless

When building an IoT device that relies on staying powered and unmanaged over a duration of months, battery life becomes mission critical. Velvetwire was trying to solve that challenge when they discovered Blues Wireless. They were faced with finding or building an affordable connectivity solution with global coverage and one that could collect and ship myriad sensor data over several months without draining the battery.

The Blues Wireless Notecard was designed for real world applications, and as such it provides extremely lightweight and intermittent connectivity. This enables the Notecard to have a typical idle current consumption of ~8uA at 3.3V, while still supporting active communication. Velvetwire leveraged Blues Wireless as an extension of their development team, working side by side to make product improvements and accelerate their time to market.

“The technical team at Blues has been really helpful to us. Together we’ve discovered enhancements and features that make the Notecard better and make our product better along the way.” – Eric Bodnar, Founder & CEO Velvetwire

Read the Velvetwire Customer Story

Vaccine cold chain monitoring is just one of the critical global issues Velvetwire’s technology is addressing. Their IoT condition monitoring solution is useful for monitoring valuable assets in motion or in remote locations. To read Velvetwire’s full customer story, please head to the Customer Stories section at Blues.io.